Our core competencies consist of two key nanomagnetic technologies.

Magnetic Sensors

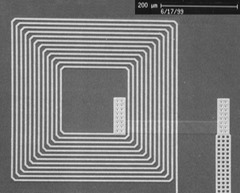

The most critical core technology is the fabrication of ultra-sensitive magnetic sensors from high temperature superconductors. Superconducting Quantum Interference Devices (SQUIDs) are the most sensitive class of magnetic field detectors known. The SQUID sensor can be most simply thought of as an ultra sensitive amplifier. The SQUID magnetometer incorporates an integrated pickup coil, which can be viewed analogous to an antenna.

The SQUID magnetic sensor forms the crucial component in our new instrumentation designed to detect small (50-500 nm) magnetic nanoparticles. Using high temperature superconductors (which garnered the Nobel prize in Physics in 1987), SQUIDs can be operated simply and inexpensively using a small refrigerator called a cryocooler. With a refrigerator, the cooling that used to be a significant obstacle to bench top instrumentation, is now essentially invisible to the user.

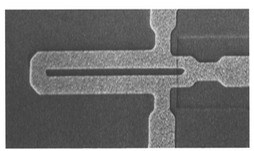

Historically, the challenge has been in developing high temperature SQUIDs that are sensitive, reliable, and manufacturable in quantity. We developed and patented a key junction nanotechnology that readily enables the fabrication of very sensitive high temperature SQUIDs that are robust (SQUID chips in our lab often last over five years and have been used to measure over a thousand magnetic assays). The junction fabrication relies upon the ability to easily and reproducibly fabricate junctions with very small (10-40 nm) dimensions. The unique combination of MagneSensors device sensitivity and manufacturability was first published in Nature. Along with reliability, these set MagneSensors apart from potential competitors for commercialization of the technology.

The SQUID sensors are fabricated in a clean room environment using equipment and processes that have been adapted from the semiconductor industry. These techniques consist of depositing and patterning thin films of superconductors on wafers.

Magnetic Nanoparticles

The innovation centers on the synthesis of next generation magnetic nanoparticle labels that are tailored specifically for magnetic detection. Most commercially developed magnetic nanoparticles are made for cell separation and sorting applications and are not well suited for magnetic detection (aggregation, too large, too weak, poor coating).

Our magnetic nanoparticles are synthesized for: 1) larger magnetic moment and 2) surface chemistry modifications on the magnetic nanoparticles to attach antibodies (or DNA probes) and to enable stability in blood. Proprietary coatings are used to reduce non-specific binding and to minimize aggregation. We synthesize Fe3O4 magnetic nanoparticles for an optimal combination of high magnetic signal, ease of synthesis, and useful coatings.

Different magnetic detection assay applications also benefit from different size magnetic nanoparticles and our synthesis process allows us to produce optimally sized magnetic nanoparticles (currently 60-350 nm) for various applications.

We expect that these tailored magnetic nanoparticle labels will significantly increase the sensitivity of the magnetic assays and ultimately provide a sizable reagent revenue source.

Recent studies have also shown that our magnetic nanoparticles work very well for magnetic cell separation and hence could benefit this sizable and growing market.